A Roller Bearing Company With Agility

Cylindrical Roller Bearing

Bearing introduction

What is a cylindrical roller bearing?

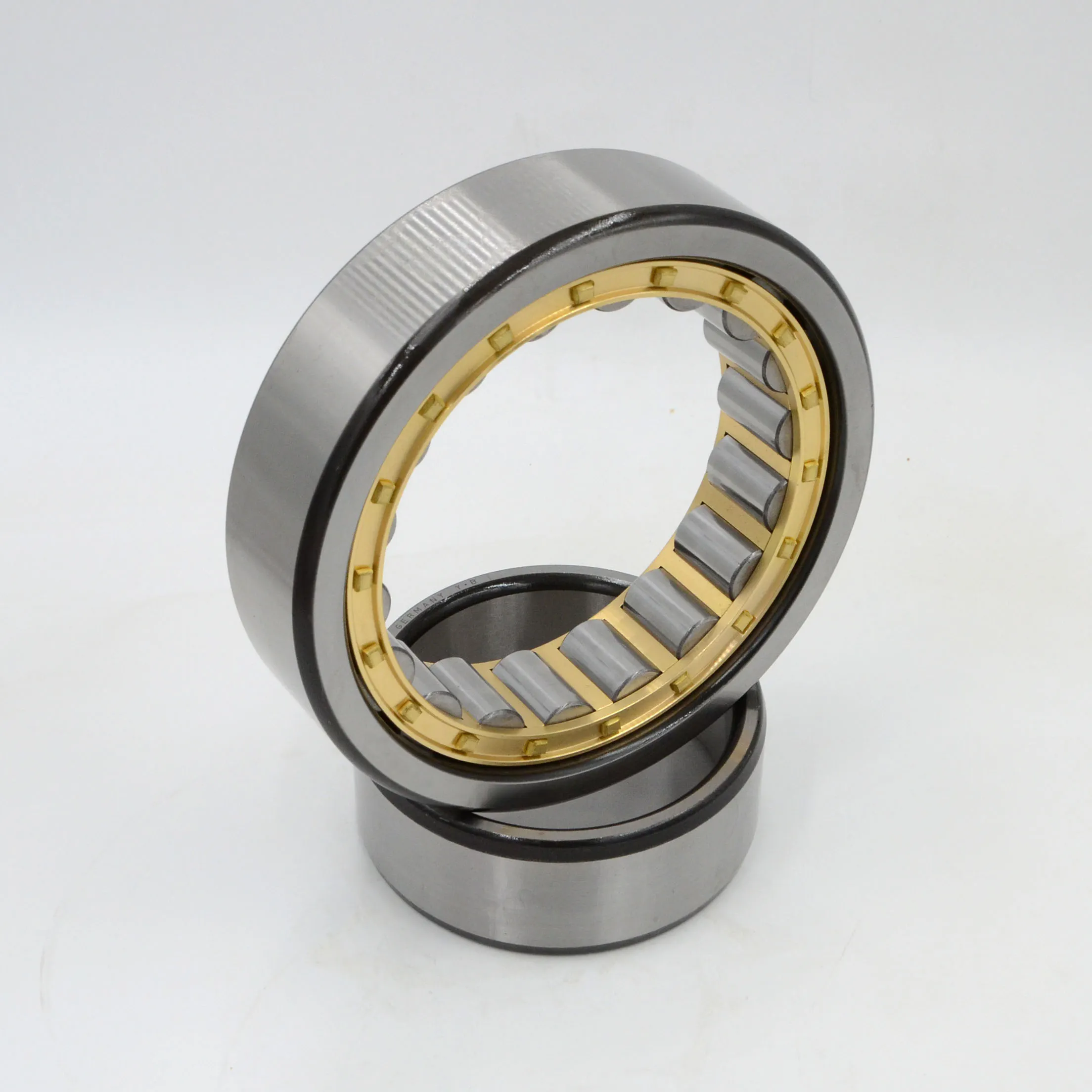

A cylindrical roller bearing, which contains only one rib in the bearing either, fits in the inner or outer ring of the bearing packed in the cage design. Such cylindrical roller bearings can go through some axial load in one direction, and these bearings are called single-row cylindrical roller bearing.

The double row cylindrical roller bearing can resist high radial load capacity. The double row cylindrical roller bearing is used to improve the efficiency of different machine tools.

The four-row cylindrical roller bearing is the best to carry very high radial loads because of the number of rolling elements present in these bearings and the four rows. These things make this bearing heavy-duty and high-speed bearings. Cages for multi-row rollers commonly use a machined brass finger cage or a mild steel finger cage. Still, larger sizes use a steel pin-type cage with hollow rollers.

Pressed steel or machined brass are the most common materials to form cylindrical roller-bearing cages. Still, some use molded polyamide, making running bearings smoother and quieter. Hardened high carbon steel or carburized low carbon steel enhances bending fatigue and handles heavy shock loads when necessary.

Components and Materials

Company Profile

About Us

Established in 2003 and headquartered in China, EPT Group is a Chinese precision bearing manufacturer producing high-quality roller bearings. we provide a variety of bearings, such as spherical roller bearings, cylindrical roller bearings, tapered roller bearings, deep groove ball bearings, angular contact ball bearings, etc. The products are widely used in metallurgy, chemical industry, coal, papermaking, cement building materials, machinery and equipment, and other industries.

Years of Experience

Exporting Country

Satisfied Customers

What are the advantages of Cylindrical Roller Bearing?

The advantages of using cylindrical roller bearing in different applications are as follows:

- Greater radial load capacity compared to ball bearings.

- Suitable for high speed applications.

- Interchangeable design Inner Ring can exchanged.

- Accommodates axial displacement.

- Separable design for simple mounting & dismounting.

- Long bearing life, support significant radial loads, robust

- These bearings reduce the amount of friction of machinery and increase its working efficiency.

- It has low maintenance cost.

Single Row Cylindrical Roller Bearing

Single row cylindrical roller bearings are a kind of cylindrical roller bearings manufactured with snap ring grooves on the outer rings. This design simplifies the bearing joint as the bearings are located in the housing using the snap rings. These single-row cylindrical roller bearings feature separable bearing rings, rollers, and cage assembly units.

Single Row Full Complement Cylindrical Roller Bearing

Single row full complement cylindrical roller bearings have solid outer and inner rings and rib-guided cylindrical rollers. Since these bearings have the most significant number of rolling elements, they have extremely high radial load carrying capacity and rigidity and are suitable for particularly compact designs.Semi-locating bearings with open design.

Double Row Cylindrical Roller Bearing

Double-row cylindrical bearings are designed for additional strength in carrying radial loads. These bearing types are interchangeable, so the dimensions and diameter under the rollers (NNU style) and diameter over the rollers (NN style) are held to an ISO/DIN standard. Interchangeability is designed for the ring without the rollers to allow interchange with competitor inner rings.

Double Row Full Complement Cylindrical Roller Bearing

A double row full complement cylindrical roller bearing is a kind of cylindrical roller bearing. Double row full complement cylindrical roller bearings are designed to withstand heavy loads. Under the same width, this kind of bearing has a very high load carrying capacity compared with the traditional bearing with a cage; the radial section is small and can save space, but the speed is relatively low.

Four Row Cylindrical Roller Bearing

Four-row cylindrical roller bearings are one of the main bearings for rolling mills, which consist of three kinds of structures: FC, FCD, and FCDP, which have a compact design, good rigidity, and high radial load capacity but can not take the axial load. Our Four-row Cylindrical Roller Bearings are especially suitable for high-speed and high-precision rollers, such as wire mills, profile mills, sheet cold rolling mills, etc.

Split Cylindrical Roller Bearing

Split cylindrical roller bearings have a row of cylindrical rollers and cylindrical inner and outer ring raceways. Split cylindrical roller bearings are used in rolling machinery where mounting, dismounting, and maintenance are complicated. They are usually installed in boxes suitable for different types of enclosures. Split cylindrical roller bearings are available in many products and can be used in industries such as rolling mills, ships, and paper machinery.

Application field

What is Cylindrical Roller Bearings used for?

Wind Turbines

The cylindrical roller bearing In wind turbines makes them smoothly revolve. These bearings make the wings of the turbine revolve according to the air pressure exerted on them.

Gearboxes

The cylindrical roller bearing is involved in the automotive field due to its use in Gearboxes and transmissions. The double row cylindrical roller bearing fits as the best machinery tool to decrease the friction rate of these appliances.

Pumps

These bearings are used in pumps for pumping fluids. The cylindrical roller bearings work as a gadget that can lift the high radial load with high speed and efficient performance.

We promise we will offer the best price by the high quality in china! We also accept particular orders about the products. We promise that our products will be safe and were in high quality, and reasonable price. If you are interested in our products, please get in touch with us asap. We are sincerely looking for your cooperation.

Cylindrical Roller Bearing

Components

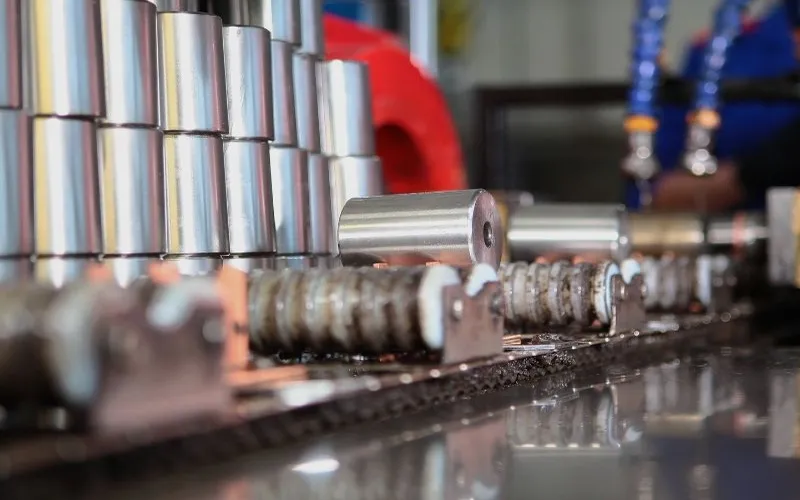

Rollers

Rings

Cages

and learn more

Cylindrical roller bearings are manufactured into single, double, or multi-row configurations. The different types of bearings are designated NU, NJ, NP, NUP, N, and NF for single-row cylindrical bearings and NNU and NN for double-row cylindrical bearings.

The range of cylindrical roller bearings is made up of many types and often denote differences in the inner ring or outer ring design:

Single row cylindrical roller bearings – commonly NU, NJ, NUP, and N designs.

Double row cylindrical roller bearings – NNU and NN designs.

Single row full complement cylindrical roller bearings – mainly NCF and NJG designs.

Double row full complement cylindrical roller bearings – NNF design.

The most popular configuration is the single-row cylindrical roller bearing. This is due to simple assembly, mounting, and un-mounting procedures, thanks to their separability; where the overall single-row design, the double and multi-row configurations offer a greater radial load capacity and higher radial rigidity.

Cylindrical Roller Bearings are classified into the following types: location, quantity, and type of ribs on the inner and outer rings.

NU, N, and NN are often free-end (“free” or “float”) bearings and are installed on the shaft away from the drive end. NJ and NF offer axial resistance in one direction, while the NUP offers axial resistance in both directions, can be used as fixed-end bearings, and is installed near the drive.

Have a Question?

Talk to the cylindrical roller bearing

FAQ

Frequently Asked Questions

The inner structure of the cylindrical roller bearing adopts parallel rollers. Between the rollers, spacers or spacers are installed, which can prevent the inclination of the rollers or friction between the rollers and effectively prevent the increase of torque. If you want to know more about cylindrical roller bearing, please read the following.

What are the design features of cylindrical roller bearing?

How are cylindrical roller bearing constructed?

Why disassemble cylindrical roller bearing?

What should be paid attention to when using cylindrical roller bearing?

In regular use, vibration is very sensitive to bearing damage, spalling, indentation, rust, crack, wear, and so on will be reflected in bearing vibration measurement. Therefore, the size of the vibration can be measured using a particular bearing vibration measuring device, and the specific circumstances of the abnormal can be inferred through the frequency distribution.

2. Temperature

The high temperature often indicates that cylindrical roller bearings have been in abnormal conditions. High temperature is also harmful to the lubricant of bearings. Sometimes bearing overheating can be attributed to the lubricant of the bearing. If the bearing is transferred continuously at a high temperature for a long time, the life of the bearing will be reduced. The reasons for high-temperature bearings include insufficient lubrication or too much lubrication, impurities in the bearing raceway, excessive limit speed, long-term overload operation of the bearing, etc.

What are the differences between cylindrical roller bearing and needle roller bearing?

1. The rolling body of cylindrical roller bearing is a tapered roller shaft; The rolling body of needle roller bearing is a needle-like roller;

2. The structure of cylindrical roller bearing is more significant than that of needle roller bearing.

3. In addition to the radial force, the cylindrical roller bearing can also bear axial force, while the needle roller bearing can only bear radial force;

4. Cylindrical roller bearing is divided into single row, double row, and multiple rows, which are applied to different environments and occasions respectively;

5. The working speed of cylindrical roller bearing is higher than that of needle roller bearing;

6. Cylindrical roller bearing is generally made of high-quality bearing steel and special steel; Thin-wall needle roller bearing is made of steel plates.

What are the characteristics of cylindrical roller bearing?

2. The processing requirements of the shaft or seat hole are high. The relative deviation of the outer ring axis should be strictly controlled after the bearing installation to avoid the concentration of contact stress.

3. The inner or outer ring can be separated for easy installation and disassembly.

4. Cylindrical roller bearing raceway and rolling body is in a geometric shape.

Related Products

Other Type Bearings

The internal structure of crossed roller bearings adopts the rollers arranged in a 90° vertical cross-arrangement. This design enables cross roller bearings to withstand radial, axial, and moment loads in all directions. At the same time, the size of the inner and outer rings is minimized, especially the ultra-thin form is a small size close to the limit and has high rigidity, so it is suitable for the joint parts or rotating parts of industrial robots and the rotary table of machining centers.

The Spherical roller bearings have a double row of rollers, the outer ring has a standard spherical raceway, and the inner circle has two raceways and is inclined to an angle relative to the bearing axis. This ingenious structure enables it to have automatic self-aligning performance, so it is not susceptible to the influence of the Angle between the shaft and the bearing box seat on the error or shaft bending. It is suitable for the occasion of Angle error caused by the installation error or shaft deflection.

Thrust roller bearings are used to bear the combined axial and radial load, mainly the axial load. Still, the radial load shall not exceed 55% of the axial load. Compared with other thrust roller bearings, this type has lower friction, higher speed, and self-aligning performance.Thrust roller bearings are commonly used in gearboxes, pulp, paper processing equipment, cranes, automotive, tractors, electric motors, pumps, and other components.

The rolling elements of needle roller bearings are a kind of cylindrical rollers, very slender (the length of the roller is 3-10 times the diameter, and the diameter is generally not greater than 5mm), so the radial structure is compact. When its inner diameter and load capacity are the same as other types of bearings, its radial section is the smallest, especially suitable for the shafting design with limited radial installation dimensions.

Tapered Roller Bearings are composed of an inner ring, outer ring, and sharp rolling elements. Thanks to the geometry of their design, tapered roller bearings can withstand combined loads (axial and radial). In addition, this design allows rolling movement without the rollers slipping off the tracks of the outer and inner rings. The contact angle of the tapered roller bearings on the rolling tracks is variable. As with other roller bearings, tapered roller bearings must be given a minimum load.

Contact Us Anytime

EPT Bearing Corporation is Your Partner!

As experts in custom bearing engineering, we can offer far more than the standard bearing manufacturer.